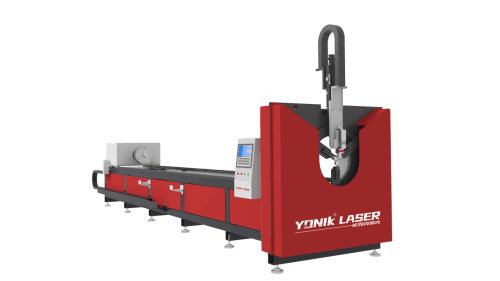

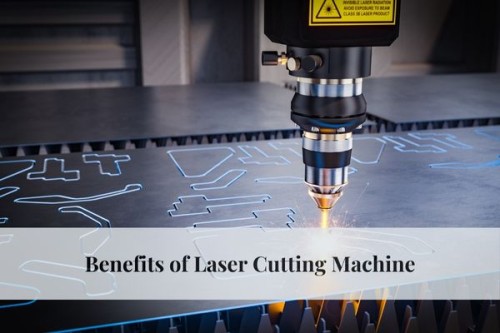

In today's fast-paced manufacturing world, the demand for precision, efficiency, and versatility in cutting technologies is higher than ever. Laser-cutting machines have emerged as a revolutionary solution, offering a range of benefits that traditional cutting methods simply cannot match. From intricate designs to mass production, laser cutting has transformed industries across the globe. This comprehensive guide will explore the numerous benefits of laser cutting machines, how they work, and why they are the preferred choice for many businesses.

Understanding Laser Cutting Technology

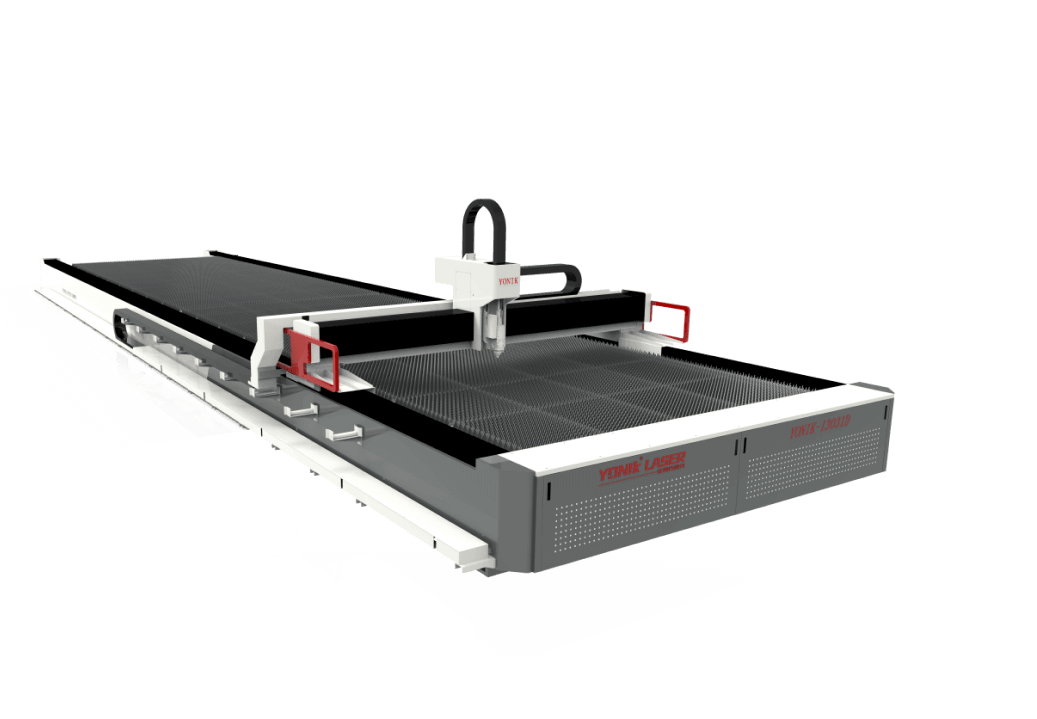

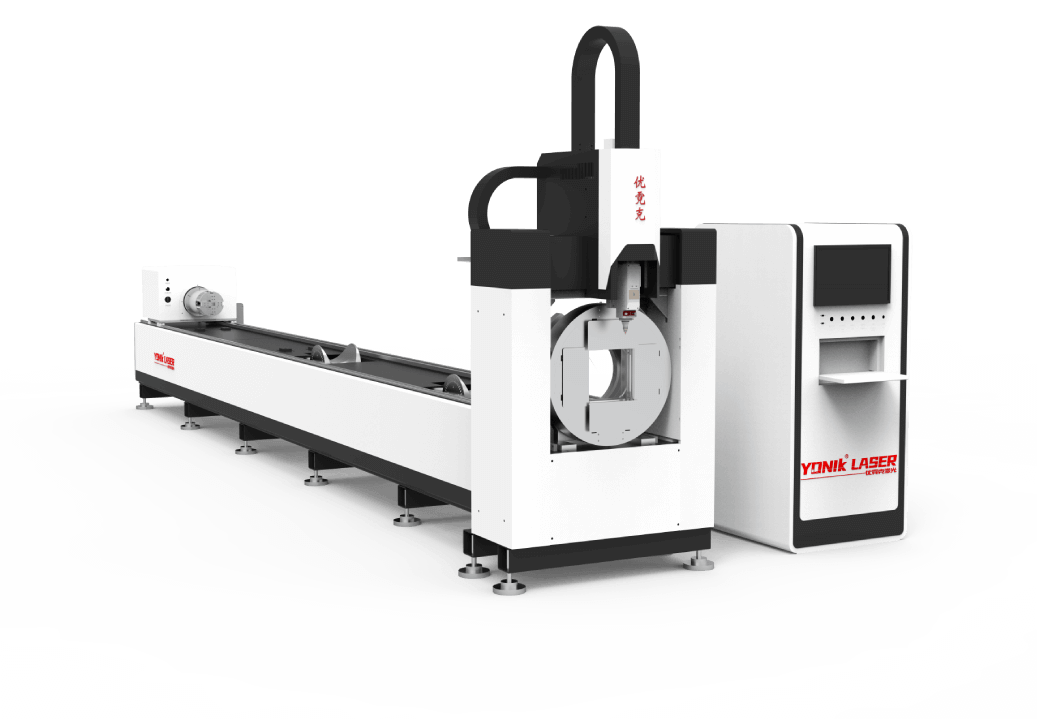

Before diving into the benefits, it’s important to understand how laser-cutting technology works. A laser cutting machine uses a focused beam of light, or laser, to cut materials. The laser beam melts, burns, or vaporizes the material, producing a high-quality finish. The precision of the laser is controlled by computer numerical control (CNC) software, allowing for intricate and accurate cuts.

Precision and Accuracy

Superior Cutting Precision

One of the most significant advantages of laser-cutting machines is their precision. The laser beam is extremely narrow, allowing for detailed and intricate designs that would be difficult or impossible with traditional cutting tools. This level of precision is crucial for industries like aerospace and automotive, where even the slightest error can lead to costly consequences.

Consistent Results

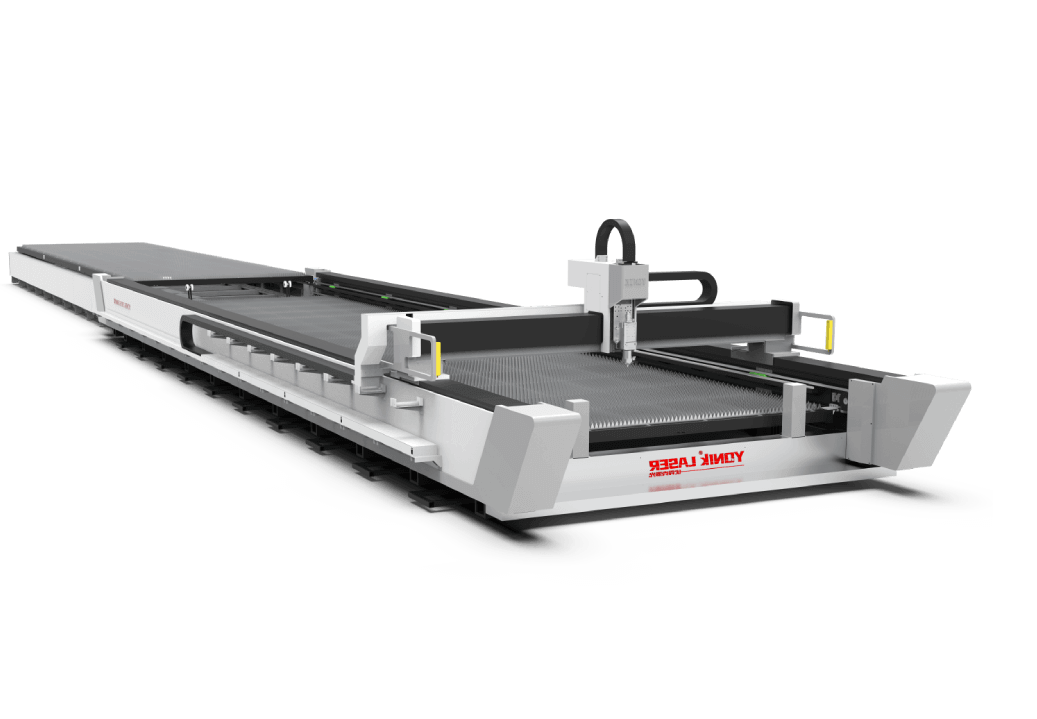

Laser-cutting machines provide consistent results across multiple runs. This is especially important for businesses that require uniformity in their products. The CNC software ensures that each cut is identical to the last, reducing waste and improving efficiency.

Speed and Efficiency

Faster Cutting Speeds

Laser-cutting machines operate at high speeds, making them ideal for mass production. The speed of the laser allows for quick turnaround times, which is a significant advantage for businesses looking to meet tight deadlines.

Minimal Setup Time

Unlike traditional cutting methods that require extensive setup and tooling, laser cutting machines have minimal setup times. The CNC software allows for quick adjustments and changes, increasing overall productivity.

Versatility in Material Cutting

Wide Range of Materials

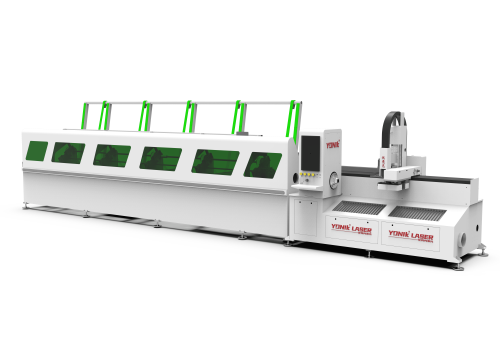

Laser-cutting machines can cut various materials, including metals, plastics, wood, glass, and textiles. This versatility makes them suitable for various industries, from fashion to engineering.

Complex Shapes and Designs

Another benefit of laser-cutting machines is their ability to cut complex shapes and designs. Whether it's a simple circle or an intricate lace pattern, the laser's precision allows for creativity and innovation in design.

Cost-Effectiveness

Reduced Material Waste

The precision of laser cutting minimizes material waste, which translates to cost savings. The narrow laser beam ensures that cuts are made with minimal excess material, reducing the overall cost of production.

Lower Energy Consumption

Modern laser cutting machines are designed to be energy-efficient. They consume less power than traditional cutting methods, making them a cost-effective option for businesses looking to reduce their energy bills.

Enhanced Safety Features

Reduced Risk of Injury

Laser-cutting machines have advanced safety features that reduce the risk of injury. The cutting process is automated and enclosed, minimizing the chance of accidents that are common with manual cutting tools.

Cleaner Work Environment

The precision of laser cutting produces minimal dust and debris, resulting in a cleaner work environment. This is particularly beneficial in industries where cleanliness is a priority, such as food packaging and medical device manufacturing.

Environmental Benefits

Eco-Friendly Technology

Laser cutting is considered an eco-friendly technology. The reduced material waste and lower energy consumption contribute to a smaller carbon footprint, aligning with the growing demand for sustainable manufacturing practices.

Recyclable Byproducts

The byproducts of laser cutting, such as dust and small particles, are often recyclable. This adds another layer of environmental benefits, as businesses can reduce their overall waste output.

Automation and Integration

Seamless Integration with CAD Software

Laser-cutting machines integrate seamlessly with CAD software, allowing for easy design modifications and updates. This integration streamlines the production process, reducing the time from design to final product.

Automated Production

The automation capabilities of laser-cutting machines enhance productivity and efficiency. Businesses can operate machines with minimal supervision, freeing up resources for other tasks.

Industries Benefiting from Laser Cutting

Automotive Industry

In the automotive industry, laser cutting is used to precisely cut body panels, intricate parts, and interior components. The accuracy and speed of laser cutting improve production efficiency and quality.

Aerospace Industry

For the aerospace industry, where precision is paramount, laser cutting provides the accuracy needed for components and materials. This technology is used for everything from cutting metal sheets to creating complex parts.

Fashion and Textile Industry

Laser cutting has revolutionized the fashion and textile industry by enabling intricate patterns and designs on fabrics. The precision and speed of laser cutting allow designers to bring their creative visions to life.

Challenges and Considerations

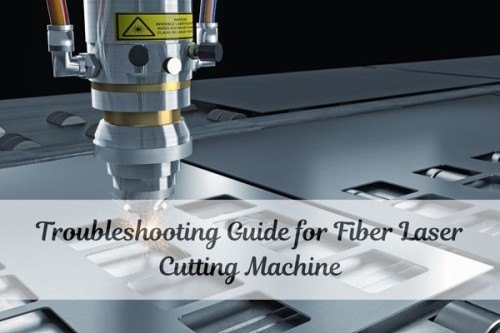

Initial Investment

While laser-cutting machines offer numerous benefits, the initial investment can be significant. Businesses need to weigh the upfront costs against the long-term savings and efficiencies gained from using laser cutting technology.

Maintenance and Training

Proper maintenance and training are essential to ensure the longevity and performance of laser-cutting machines. Regular maintenance and operator training can prevent downtime and extend the machine’s lifespan.

The Future of Laser Cutting Technology

As technology advances, laser-cutting machines' capabilities are expected to grow. Innovations such as increased cutting speeds, improved energy efficiency, and enhanced precision will make laser cutting even more appealing to a broader range of industries. The future of laser-cutting technology promises even greater versatility and efficiency, solidifying its place as a key player in modern manufacturing.

Conclusion

The benefits of laser-cutting machines are undeniable. From their precision and speed to their versatility and eco-friendliness, laser cutting technology has transformed how industries approach manufacturing. Whether in automotive, aerospace, fashion, or any other industry, incorporating laser cutting into your production process can improve efficiency, reduce costs, and enhance product quality. As businesses continue to seek innovative solutions, laser-cutting machines offer a powerful tool for meeting the demands of the modern market.