Available

Available

Laser Tube Cutting Machine For Front Pulling

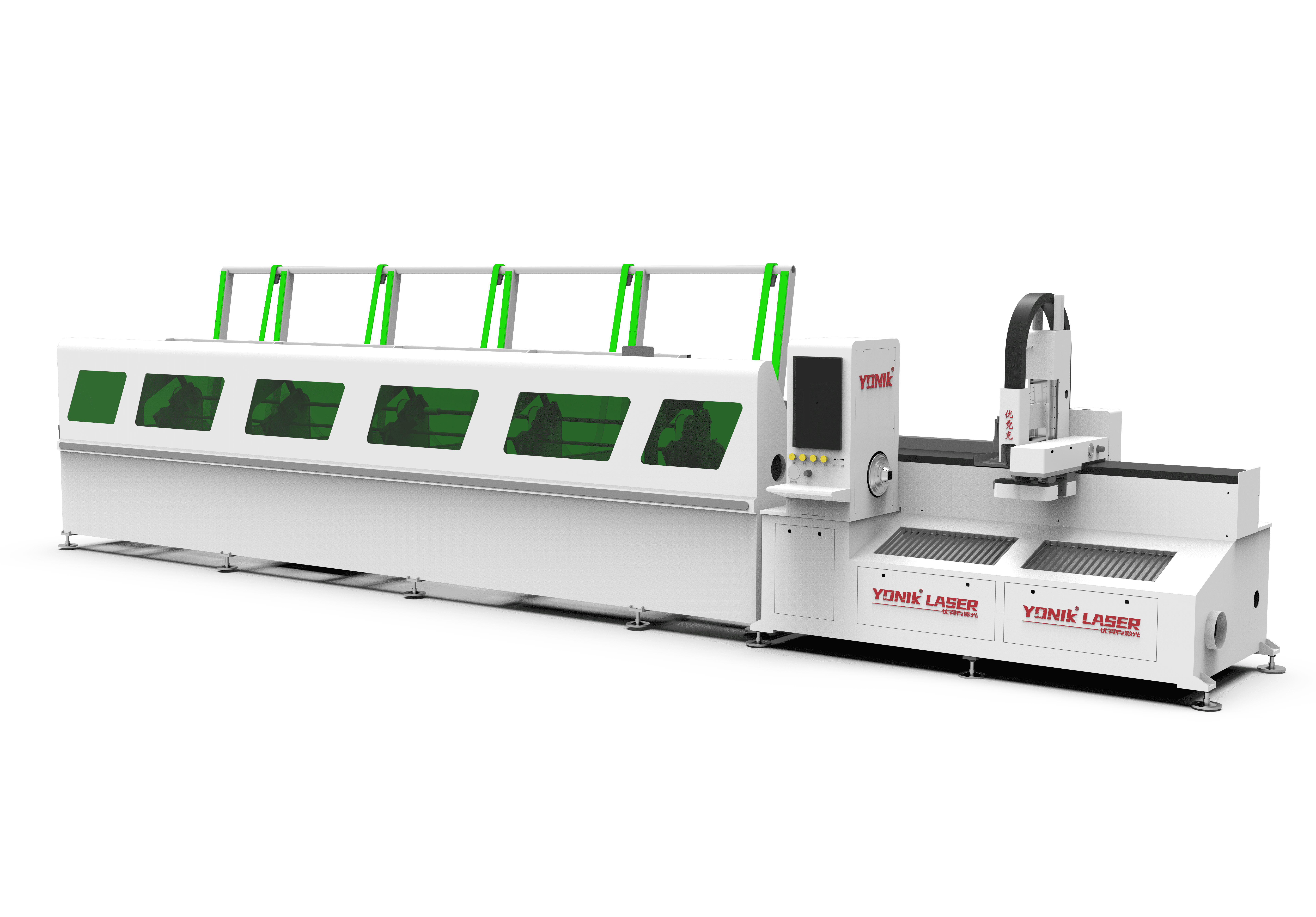

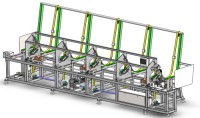

Laser Tube Cutting Machine for Front Pulling Product Introduction (1) Machine Overview The 6009K laser pipe cutting machine is a specialized solution designed for the pipe structure manufacturing industry, catering to applications in furniture, medical equipment, sports equipment, boiler and pressure vessel manufacturing, and the chemical equipment industry. Offering high efficiency, precision, and automatic loading/unloading capabilities, it cuts round tubes, square tu

- Color: Default Color

- Size: Default Size

- Origin: China

- Usage: Default Usage

- Type: Default Type

- Efficiency: 99.9% Type

Description:

Laser Tube Cutting Machine for Front Pulling

Product Introduction

(1) Machine Overview

The 6009K laser pipe cutting machine is a specialized solution designed for the pipe structure manufacturing industry, catering to applications in furniture, medical equipment, sports equipment, boiler and pressure vessel manufacturing, and the chemical equipment industry. Offering high efficiency, precision, and automatic loading/unloading capabilities, it cuts round tubes, square tubes, and rectangular tubes with exceptional stability and precision. Featuring a sleek design, compact structure, smooth operation, and user-friendly controls, this model ensures a beautiful appearance and easy handling. The transmission system, equipped with imported gear racks, servo motors, reducers, and linear guides, enhances stability and ensures high-precision, high-quality cutting.

(2) Machine Performance

Independent research and development of machine tool beds, incorporating special processing technology for high precision, stability, reliability, and an extended lifespan.

Precision rack and pinion drive with a high-precision reducer, coupled with a responsive, high-precision servo motor.

Utilizes an international first-class quality fiber laser, renowned for its industrial application, long life, maintenance-free operation, and stability.

High-precision laser cutting head with imported optical lenses, enabling fine focusing, easy adjustment, and flawless cutting.

Simple and easy-to-learn CNC system operation with low operator requirements.

Supports multiple cutting graphics formats, offering powerful graphics drawing and editing functions.

Includes an automatic refueling system.

(3) Cutting Materials

Suitable for cutting a variety of metal sheets, including stainless steel, carbon steel, alloy steel, silicon steel, spring steel, galvanized sheet, and pickled sheet. Widely adopted across engineering machinery, aerospace, automotive, shipbuilding, steel structures, machinery manufacturing, elevator manufacturing, advertising, household appliances, medical equipment, and more.

2. Functional Characteristics of Each Part

(1) Technical Advantages

The Unicorn Laser Pipe Cutting Machine operates on a 4-axis digital control system, ensuring precise control. The 4 axes include X-axis (tangential deflection of the laser head), Y-axis (movement of the pipe end positioning plate), B-axis (rotation of the workpiece), and Z-axis (vertical movement of the cutting head). Driven by AC servo motors, the machine boasts a fully digital system, ensuring high stability and reliability.

(2) Equipment Chuck

Equipped with a pneumatic self-centering chuck with a 90mm inscribed circle diameter, offering efficiency in pipe replacement. Simplifying the process, only the chuck pad needs replacement, saving time and improving work efficiency.

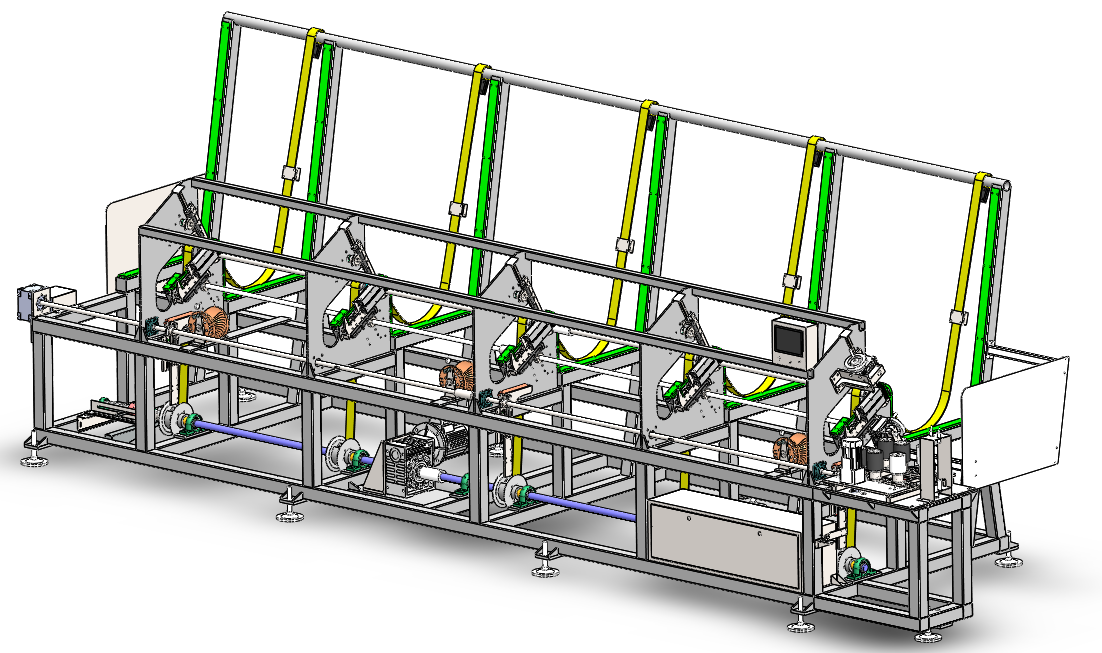

(3) Feeding Rack

Material placement in the pocket with the pipe lifted to the sliding table.

Lifting mechanism raises the last pipe on the sliding table.

Pipes roll into the feeding chute along the loading slope.

Feeding mechanism clamps the pipe and sends it to the main machine.

(6) Fiber Laser Generator

Modular and redundant design, compact, and lightweight for easy integration.

High electro-optical conversion efficiency, reducing power consumption and operating costs.

Operates solely on electrical energy, minimizing maintenance costs.

Semiconductor modular and redundant design for adjustment-free, maintenance-free, and high stability.

Simple optical path through fiber transmission, ensuring stability and maintenance-free operation.

Compact, lightweight, removable, and space-efficient design.

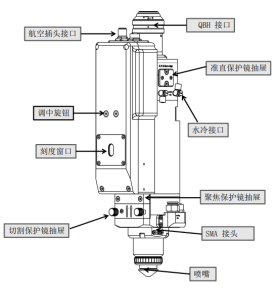

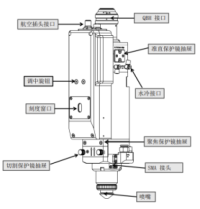

(7) Fiber Laser Cutting Head

Internally sealed structure to prevent optical part contamination.

Driven by an imported motor for high punching efficiency.

Adaptive optical system for automatic focus or spot size adjustment, ensuring consistent cutting quality.

Sealed and dust-proof three-piece protective mirror for extended service life.

Automatic machine tool stop in case of cutting head collision.

(8) Operating System

Face sorting for reduced rotations and improved processing efficiency.

Automatic extraction of the pipe section to be cut and trajectory without manual editing.

Fast and convenient automatic leveling and center correction functions for enhanced cutting accuracy.

Automatic calculation of lifting height during pipe rotation, avoiding head collision, and saving time.

Compensation for regular cutting deviations, reducing material accuracy requirements and minimizing waste.

Effective solution for pipe hole position accuracy, improving edge distance accuracy.

Cutting head alignment for reduced manual alignment time and front-end waste.

Pulling gripper for adaptive pulling, ensuring constant feeding stroke.

Automatic extraction of the pipe section and trajectory, eliminating manual editing.

(9) Cooling Method

Utilizes a professional-grade water cooling system with dual temperature and dual control. Digital meter display for temperature monitoring, ensuring automatic cooling when needed.

718

718