|

Products

|

Products  Tube Metal Laser Cutting Machine

Tube Metal Laser Cutting Machine

Universal Economical Round Square Tube Laser Cutting Machine

Universal Economical Round Square Tube Laser Cutting Machine

Available

Available

Universal Economical Round Square Tube Laser Cutting Machine Product Introduction (1) Machine Overview The Unico laser pipe cutting machine is a versatile laser cutting solution tailored to the needs of batch pipe processing end-users. With exceptional cost-effectiveness, it efficiently handles round tubes, square tubes, and rectangular tubes up to 12.5 meters in length. From configuration selection to assembly, training, and after-sales support, this machine stands o

Universal Economical Round Square Tube Laser Cutting Machine

The Unico laser pipe cutting machine is a versatile laser cutting solution tailored to the needs of batch pipe processing end-users. With exceptional cost-effectiveness, it efficiently handles round tubes, square tubes, and rectangular tubes up to 12.5 meters in length. From configuration selection to assembly, training, and after-sales support, this machine stands out for its affordability and user-friendly design. The transmission system, featuring imported gear racks, servo motors, reducers, and linear guides, ensures enhanced stability, high precision, and superior cutting capabilities.

Ideal for cutting stainless steel, carbon steel, alloy steel, silicon steel, spring steel, galvanized sheet, pickled sheet, and various other metal sheets. Widely applied across manufacturing industries such as engineering machinery, aerospace, automobiles, ships, steel structures, machinery manufacturing, elevator manufacturing, advertising production, household appliances, medical equipment, stair handrails, steel and wood furniture, and metal external processing services.

The lathe bed, developed independently, incorporates structural dynamic design principles and variable analysis technology. Constructed with high-quality raw materials, it undergoes stress relief annealing, secondary vibration aging treatment, and precision machining on a large gantry milling machine. This ensures excellent shock resistance, high rigidity, stability, good toughness, light weight, corrosion resistance, oxidation resistance, and high processing speed.

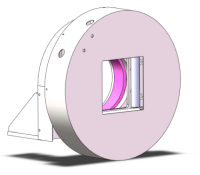

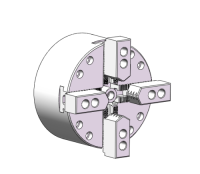

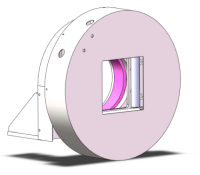

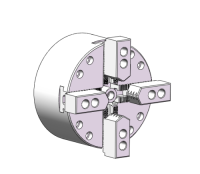

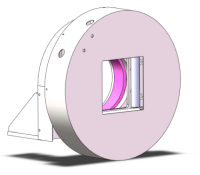

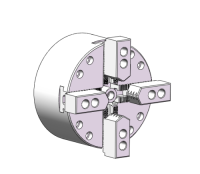

The Unico laser chuck R&D team showcases innovation with strong R&D capabilities and multiple patents. With independent intellectual property rights, the chuck offers superior throughput capacity, accommodating round tubes or square tubes with a diameter or side length of up to 450mm. The precision screw drive ensures robust power and high efficiency, while the front chucks ability to move and avoid the cutting head allows for ultra-short tail material cutting with two chucks.

Professional-grade water cooling system with dual temperature control. Two waterways cool two core locations respectively, with automatic cooling based on digital meter readings.