Available

Available

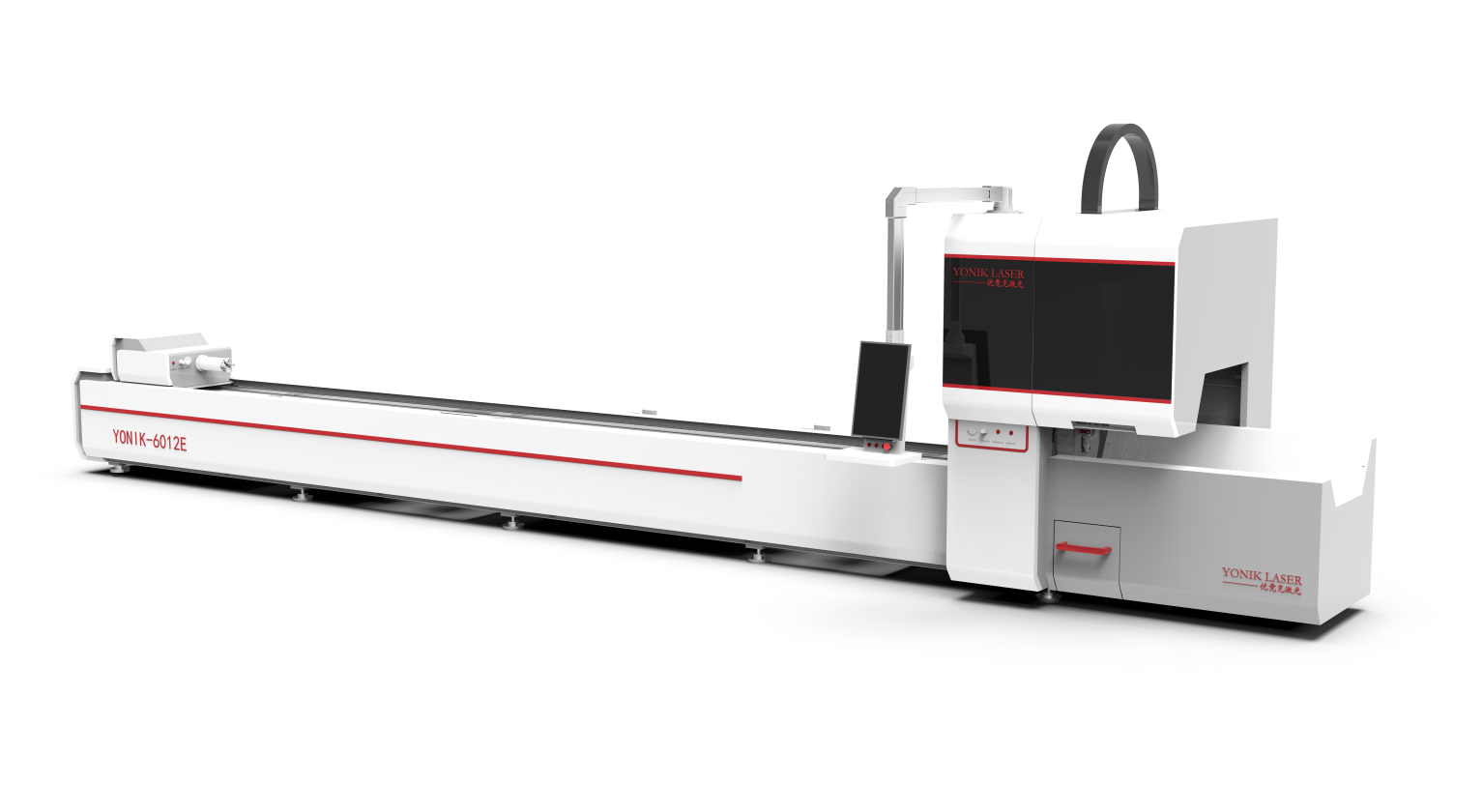

Bevel Laser Tube Cutting Machine

Bevel Laser Tube Cutting Machine Product Advantages 1.1 Highly Tolerant for Versatile Metal Pipes Our Bevel Laser Tube Cutting Machine stands out for its exceptional tolerance, making it suitable for various types of metal pipes of diverse shapes. Whether dealing with round, square, or rectangular tubes, this machine effortlessly accommodates the unique requirements of each. 1.2 Intelligent Operating System with Rich Cutting Functions Featuring an inte

- Color: Default Color

- Size: Default Size

- Origin: China

- Usage: Default Usage

- Type: Default Type

- Efficiency: 99.9% Type

Description:

Bevel Laser Tube Cutting Machine

Product Advantages

1.1 Highly Tolerant for Versatile Metal Pipes

Our Bevel Laser Tube Cutting Machine stands out for its exceptional tolerance, making it suitable for various types of metal pipes of diverse shapes. Whether dealing with round, square, or rectangular tubes, this machine effortlessly accommodates the unique requirements of each.

1.2 Intelligent Operating System with Rich Cutting Functions

Featuring an intelligent operating system, our machine offers a seamless user experience with a plethora of cutting functions. This ensures versatility and precision in meeting a wide range of cutting needs.

1.3 High-Speed Cutting with 350mm Chuck

Equipped with a powerful 350mm chuck, our machine achieves high-speed cutting with two rotations per second. This capability significantly enhances productivity and efficiency in the cutting process.

1.4 Follow-Up Servo Support for Precise Positioning

The follow-up servo support system ensures precise positioning during the cutting process. It adapts to the height of the rotating pipe in real-time, offering optimal support and contributing to the overall accuracy of the machine.

1.5 Minimal Tailings

Our Bevel Laser Tube Cutting Machine is designed to produce minimal tailings, reducing material waste. This feature enhances cost-effectiveness and promotes eco-friendly manufacturing practices.

2. Independent Technology

2.1 Lathe Bed

Our independently developed lathe bed incorporates structural dynamic design principles and finite element method analysis. Welded with high-quality materials, it undergoes stress relief annealing, secondary vibration aging treatment, and precision machining. This ensures outstanding shock resistance, high rigidity, stability, light weight, and corrosion resistance.

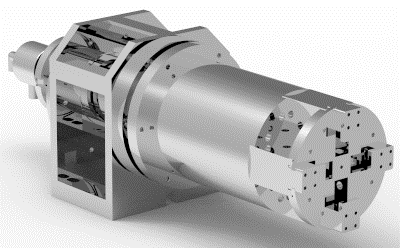

2.2 Chuck

Our laser chuck, a result of strong R&D capabilities and independent innovation, outperforms standard chucks. With features like square hole design, intelligent clamping force adjustment, and extended rear chuck design, it enhances cutting efficiency and adaptability for various pipe materials.

2.3 Follow-Up Servo Support

Developed independently by Unico Laser, the follow-up servo support system excels in handling both large and small pipes. With a self-locking indexing pin structure, it ensures excellent tolerance, supporting heavy loads and automatically adjusting to avoid interference during feeding.

2.4 Special Bevel Cutting Laser Head

(Description not provided in the original text)

2.5 Semi-Automatic Feeding

Equipped with a semi-automatic loading device, our machine facilitates automatic loading of round, square, and rectangular tubes. The feeding arm holds the tube, waits for the cutting process to complete, and then positions the tube at the center of the machine tool, optimizing material loading time.

2.6 Cutting System

The cutting system, developed based on German EtherCAT bus technology, ensures fast and accurate transmission. With features like automatic centering, special-shaped steel cutting, dual mode, seven-axis pulling, bracket functionality, and corner processing, it provides a comprehensive solution for high-end laser tube cutting CNC machine tools.

2.7 Cutting Software

The cutting software is designed for ease of operation, real-time path display, and high-precision processing. Key features include automatic centering during processing, cutting of special-shaped steel, dual mode options, seven-axis pulling support, bracket functionality, corner process optimization, and quick frog jump for enhanced efficiency during the cutting process.

Product Technical Parameters

- Model: YONIK-6035EP

- Cutting Pipe Length: 6500mm

- Cutting Pipe Diameter: Diameter Φ10-240mm

- Machine Power: 18KW

- Cutting Tail: ≥70mm

- Y-Axis Stroke: 6800mm

- X-Axis Travel: 400mm

- Z-Axis Stroke: 350mm

- Maximum Speed: 100r/min

- Control System: FSCUT5000

- Auxiliary Gas: Oxygen, Nitrogen, Air

- Machine Weight: 2.8 tons

- Machine Dimensions: 9600×2000×2200mm (Length x Width x Height)

- Chuck Load-Bearing: 300kg

- Maximum Acceleration: 1.2G

- Maximum Feed Speed: 80m/min

- Power Supply: 380v50Hz±10%

654

654